Solar Panel Glass Specifications Explained

Photovoltaic (PV) glass is revolutionizing the solar panel industry by offering multifunctional properties that surpass conventional glass.

This innovative material not only generates power but also provides crucial benefits like low-emissivity, UV and IR filtering, and natural light promotion.

The most important aspect of PV glass for solar panels is its ability to optimize performance under various climatic conditions through customizable specifications.

These include solar factor (SHGC), U-value, and light transmission, which can be tailored to meet specific architectural requirements.

By understanding these key specifications, solar panel manufacturers and project developers can enhance the efficiency and sustainability of their products, ultimately contributing to the growth of renewable energy solutions.

That said, lets go over the details of solar panel glass specifications, exploring the types, properties, and configurations that make this technology a game-changer in the solar industry.

Types of Photovoltaic Glass

Photovoltaic glass comes in two main types, each with its own unique characteristics and applications. Let’s explore these options to understand their benefits and use cases in solar panel manufacturing.

Amorphous Silicon PV Glass

Amorphous silicon PV glass is a versatile option that offers several advantages for solar panel applications:

- Customization: This type of glass can be tailored to meet the specific needs of each project, making it highly adaptable.

- Color variety: Available in a wide range of colors, allowing for greater aesthetic flexibility in design.

- Size options: Manufacturers offer the largest PV glass available in the market, with dimensions up to 4 x 2 meters.

- Transparency levels: Amorphous silicon PV glass can be produced with varying degrees of transparency, from dark (0% transparent) to high transparency (30% transparent).

The flexibility in design and performance makes amorphous silicon PV glass suitable for various architectural applications, from building-integrated photovoltaics (BIPV) to traditional solar panels.

Crystalline Silicon PV Glass

Crystalline silicon PV glass is another popular option in the solar industry, known for its high efficiency and power output:

- Customization: Like amorphous silicon, crystalline PV glass can be customized to suit project requirements.

- Color options: Available in various colors to match architectural designs.

- Size: Also available in large formats, up to 4 x 2 meters.

- Power capacity: The power output is primarily determined by the number of cells used per module, known as solar cell density.

Crystalline silicon PV glass is often chosen for projects where maximizing power output is a priority, as it generally offers higher efficiency compared to amorphous silicon.

Optical and Thermal Properties

The performance of PV glass in solar panels is largely determined by its optical and thermal properties. Understanding these characteristics is crucial for optimizing the efficiency and comfort of solar installations.

Solar Factor (SHGC)

The solar factor, also known as g-value or Solar Heat Gain Coefficient (SHGC), is a key metric in achieving thermal comfort in buildings:

- Definition: It represents the proportion of solar energy that passes through the glass.

- Range: For thin-film glass, the solar factor typically ranges from 10% to 40%.

- Impact: A lower solar factor helps control interior temperature by reducing heat gain.

For example, Onyx Solar’s thin-film glass offers solar factors as low as 5% for certain configurations, making it an excellent choice for managing heat in sunny climates.

U-Value

The U-value is a measure of thermal insulation, indicating how well the glass prevents heat transfer:

- Definition: It quantifies the rate of heat transfer through the glass, measured in W/m²K or Btu/h ft² F.

- Configurations: U-values vary depending on the glass configuration, with options including single laminated, double glazing, and triple glazing.

- Improvement techniques: Using air or argon chambers and low-E coatings can significantly reduce U-values.

For instance, a triple-glazed configuration with argon chambers and low-E coating can achieve U-values as low as 1.0 W/m²K (0.18 Btu/h ft² F), providing excellent thermal insulation.

Light Transmission

Light transmission is an important factor in balancing natural lighting with energy generation:

- Definition: It represents the percentage of visible light that passes through the glass.

- Variation: Transparency levels can range from 0% (dark) to 30% or more (high transparency).

- Trade-off: Higher transparency generally results in lower power output, so a balance must be struck based on project requirements.

Glass Configurations

PV glass can be configured in various ways to optimize performance for different applications. Let’s examine the most common configurations and their benefits.

Single Laminated

Single laminated PV glass is the simplest configuration:

- Structure: Typically consists of two glass panes with a PV layer sandwiched between them.

- Example: A common setup might be 3.2mm + 4mm thickness.

- Properties: Offers basic solar control and power generation but has limited thermal insulation.

This configuration is often used in applications where weight and cost are primary concerns, such as in certain BIPV installations.

Double Glazing

Double glazing improves upon single laminated configurations:

- Structure: Consists of a PV glass unit paired with another glass pane, separated by an air or gas-filled chamber.

- Example: A typical setup might be 6T + 3.2 + 6T / 12Air / 6T.

- Benefits: Significantly improves thermal insulation and sound reduction compared to single laminated glass.

Double glazing is widely used in building facades and windows where energy efficiency is a priority.

Triple Glazing

Triple glazing offers the highest level of thermal insulation:

- Structure: Incorporates three glass panes with two separate chambers, often filled with inert gases like argon.

- Example: A high-performance configuration might be 6T + 3.2 + 6T / 12Argon / 4 / 12Argon / 6T low-e.

- Advantages: Provides superior thermal insulation and sound reduction, ideal for extreme climates or noise-sensitive areas.

While triple glazing offers the best performance in terms of insulation, it’s important to consider the added weight and cost when specifying this option.

Key Specifications

When selecting PV glass for solar panels, several key specifications need to be considered to ensure optimal performance and compatibility with project requirements.

Thickness

The thickness of PV glass plays a crucial role in its structural integrity and performance:

- Range: Common thicknesses range from 3.2mm to 6mm for individual glass panes.

- Configurations: Total thickness varies based on the configuration (single laminated, double glazed, etc.).

- Considerations: Thicker glass provides better strength but increases weight and potentially reduces light transmission.

For example, a typical double-glazed configuration might have a total thickness of 15.2mm (6mm + 3.2mm + 6mm).

Size

PV glass is available in various sizes to suit different applications:

- Standard sizes: Many manufacturers offer standard sizes for ease of production and installation.

- Custom options: Large format PV glass, up to 4 x 2 meters, is available for projects requiring seamless integration or larger panels.

- Considerations: Larger sizes may offer better aesthetics but can be more challenging to handle and install.

When specifying size, it’s important to consider not only the desired appearance but also logistical factors such as transportation and installation.

Transparency Levels

Transparency is a key factor in balancing power generation with natural light transmission:

- Dark: 0% transparency, maximizing power output but blocking all direct light.

- Low transparency: Around 10%, offering a balance of power and some natural light.

- Medium transparency: Approximately 20%, allowing more natural light while still generating significant power.

- High transparency: Up to 30% or more, prioritizing natural light while still providing some power generation.

The choice of transparency level depends on the specific requirements of the project, such as energy goals, daylighting needs, and aesthetic preferences.

Power Output

The power output of PV glass varies based on the technology used and the configuration:

- Amorphous silicon: Typically ranges from 28 Wp/m² (high transparency) to 57.6 Wp/m² (dark).

- Crystalline silicon: Power output is primarily determined by solar cell density, with high-density configurations offering greater power generation.

It’s important to note that power output often has an inverse relationship with transparency, so the appropriate balance must be struck based on project goals.

Additional Features

PV glass offers several additional features that enhance its performance and versatility in solar panel applications.

Low-E Properties

Low-emissivity (Low-E) coatings are a valuable addition to PV glass:

- Function: These coatings reduce heat transfer through the glass by reflecting infrared radiation.

- Benefits: Improves thermal insulation, reducing heating and cooling costs.

- Integration: Can be incorporated into double and triple-glazed configurations for enhanced performance.

For example, a double-glazed configuration with Low-E coating can achieve U-values as low as 1.6 W/m²K (0.28 Btu/h ft² F), significantly improving energy efficiency.

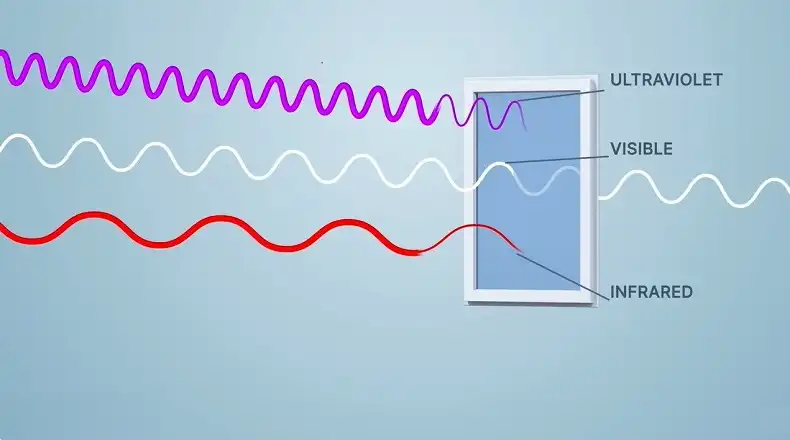

UV and IR Filtering

PV glass can be engineered to filter out harmful ultraviolet (UV) and infrared (IR) radiation:

- UV filtering: Protects interior materials from fading and degradation caused by UV light.

- IR filtering: Reduces heat gain from solar radiation, improving thermal comfort.

- Combined benefits: These features contribute to a more comfortable and energy-efficient indoor environment.

Customization Options

PV glass manufacturers offer various customization options to meet specific project requirements:

- Color variations: Available in a range of colors to match architectural designs.

- Pattern options: Some manufacturers offer patterned glass for enhanced aesthetics or light diffusion.

- Performance tuning: Specifications can be adjusted to optimize for different climatic conditions or energy goals.

This flexibility allows architects and developers to integrate PV glass seamlessly into diverse projects while meeting performance targets.

Benefits of PV Glass

Incorporating PV glass in solar panel design offers numerous advantages:

- Multifunctionality: Combines power generation with thermal insulation and light control.

- Energy efficiency: Contributes to reduced energy consumption in buildings.

- Aesthetic integration: Allows for seamless incorporation of solar technology into architectural designs.

- Customization: Can be tailored to meet specific project requirements and performance goals.

- Sustainability: Supports renewable energy goals and can contribute to green building certifications.

By leveraging these benefits, solar panel manufacturers and project developers can create more efficient, attractive, and sustainable solar solutions.

Conclusion

Photovoltaic glass represents a significant advancement in solar panel technology, offering a versatile and efficient solution for integrating renewable energy into various applications.

By understanding the key specifications and features of PV glass, including its types, optical and thermal properties, configurations, and customization options, stakeholders in the solar industry can make informed decisions to optimize their products and projects.

The multifunctional nature of PV glass, combining power generation with thermal insulation and light control, makes it an attractive option for both traditional solar panels and building-integrated photovoltaics.

As the technology continues to evolve, we can expect further improvements in efficiency, aesthetics, and customization options, solidifying PV glass as a cornerstone of sustainable energy solutions in the years to come.