Difference Between MC4 and T4 Connectors for Solar Panels

Solar panel connectors serve as the vital links in a photovoltaic system, joining panels to create strings and connecting these strings to inverters. They play a crucial role in ensuring efficient energy transfer and protecting the system from environmental factors. The choice between MC4 and T4 connectors can impact your system’s performance, safety, and long-term reliability.

What Are MC4 Connectors

Multi-Contact 4 (MC4) connectors have been the go-to choice for solar installations worldwide since their introduction in the early 2000s. Developed by Multi-Contact (now Stäubli Electrical Connectors), these connectors have become synonymous with reliability and versatility in the solar industry.

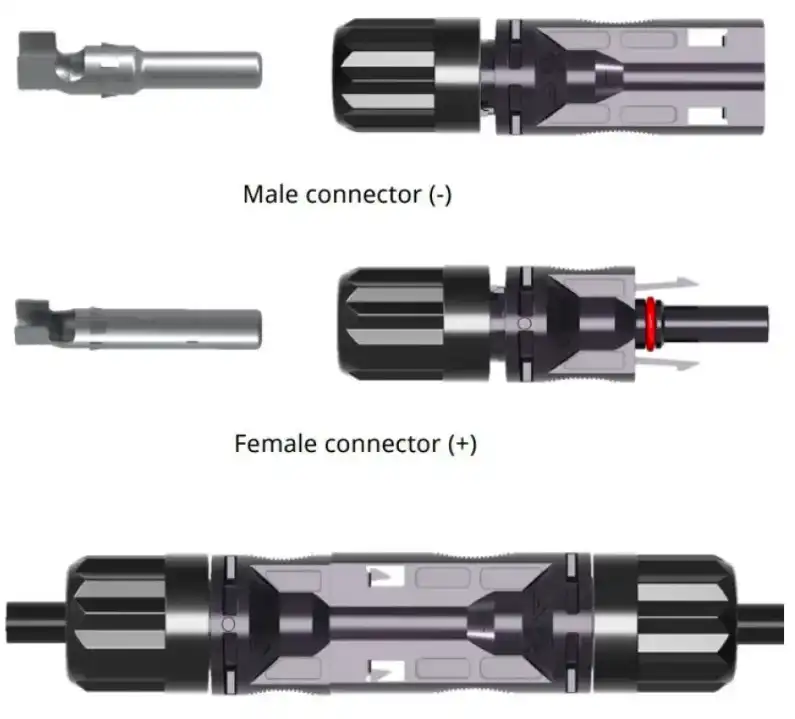

MC4 connectors consist of a male plug and a female socket, each housing a metal contact pin or socket. The housing is typically made of durable, UV-resistant plastic, while the contacts are often copper with a conductive coating. A rubber seal ensures a weather-tight connection when the two halves are joined.

Image: MC4 connector exploded view

One of the key advantages of MC4 connectors is their widespread adoption. This ubiquity means that replacement parts and compatible components are readily available, often at competitive prices. MC4 connectors are designed to handle voltages up to 1000V DC and currents up to 30A, making them suitable for most residential and commercial solar installations.

What Are T4 Connectors

T4 connectors, introduced by Tlian (a subsidiary of Canadian Solar), represent a newer entry in the solar connector market. These connectors were developed to address some of the limitations of MC4 connectors, particularly in systems with higher current requirements.

The design of T4 connectors is similar to MC4, with male and female components that lock together. However, T4 connectors boast a higher current capacity, typically rated for up to 40A, making them potentially more suitable for larger solar installations or systems using high-wattage panels.

Image: T4 connector exploded view

Despite their advantages, T4 connectors have not yet achieved the same level of market penetration as MC4. This can lead to challenges in terms of compatibility and availability of replacement parts.

Key Differences: MC4 vs T4

To better understand how these connectors stack up against each other, let’s examine their key differences:

- Current Capacity

MC4 connectors are typically rated for up to 30A, while T4 connectors can handle up to 40A. This higher current capacity makes T4 connectors potentially more suitable for larger solar systems or those using high-wattage panels.

- Market Adoption

MC4 connectors are widely used and considered the industry standard. T4 connectors, being newer, have a smaller market share. This difference affects the availability of compatible components and replacement parts.

- Compatibility

Due to their widespread use, MC4 connectors offer greater compatibility across different brands and systems. T4 connectors may have more limited compatibility, potentially requiring adapters when used with MC4-based systems.

- Cost

Generally, MC4 connectors are more affordable due to their widespread production and competition among manufacturers. T4 connectors, being less common, may come at a premium.

- Installation

Both connector types require similar installation procedures, but the greater familiarity with MC4 connectors among installers can lead to faster and potentially more reliable installations.

Here’s a comparison table to summarize these differences:

| Feature | MC4 Connector | T4 Connector |

| Current Rating | Up to 30A | Up to 40A |

| Voltage Rating | Up to 1000V DC | Up to 1500V DC |

| Market Adoption | Widespread (industry standard) | Limited |

| Compatibility | High across brands | Limited, may require adapters |

| Typical Cost | Lower | Higher |

| Availability | Widely available | Less common |

How to Pick the Right Connector for Your Solar System

When deciding between MC4 and T4 connectors, consider your system size and current requirements. For most residential and small commercial systems, MC4 connectors are typically sufficient. On the other hand, T4 connectors are usually more suitable for large commercial or utility-scale installation due to their higher-wattage panels.

However, if you are planning on future expansion which might involve shifting to higher-wattage systems, T4 connectors might make your system more future-proof.

Ensure that your chosen connectors are compatible with your panels, inverters, and other system components. Using mismatched connectors can void warranties and create safety hazards.

And if you are worried about service life and weather resistance, both of them are considered pretty durable. However, T4 connectors are generally more weather-resistant as well as durable since they come with an IP68 rating.

Other Types of Solar Panel Connectors

While MC4 and T4 connectors are among the most common, several other types of connectors are used in solar panel systems. Understanding these alternatives can provide a broader perspective on solar connection technologies.

MC3 Connectors

Predating MC4, MC3 connectors were once widely used but are now less common. They’re smaller than MC4 connectors and rated for lower currents, typically up to 20A. While some older systems still use MC3, they’re generally considered obsolete for new installations.

Amphenol H4 Connectors

Developed as an alternative to MC4, Amphenol H4 connectors are designed to be fully intermateable with MC4. They offer similar specifications but with some unique features like a patented RADSOK technology for improved electrical contact.

Tyco Solarlok Connectors

Tyco Electronics (now TE Connectivity) produces these connectors, which are designed for easy field installation without special tools. They’re available in various configurations and are known for their reliability in harsh environments.

QC4 Connectors

Quick Connect 4 (QC4) connectors, made by Renusol, are another MC4-compatible option. They’re designed for quick connections and disconnections, which can speed up installation and maintenance processes.

UTX Connectors

UTX connectors, produced by Utility Tech, are designed for higher current applications, typically rated up to 50A. They’re larger than MC4 connectors and are often used in utility-scale solar installations.

Frequent Asked Questions

Are T4 and MC4 connectors the same?

No, T4 and MC4 connectors are not the same. While they serve similar purposes in solar panel systems, they have distinct designs and specifications. MC4 connectors are the industry standard, developed by Multi-Contact (now Stäubli), while T4 connectors are a newer design introduced by Tlian, a subsidiary of Canadian Solar. They differ in current capacity, market adoption, and compatibility with other components.

What is the maximum voltage for MC4 connectors?

MC4 connectors are typically rated for a maximum voltage of 1000V DC. However, some manufacturers offer high-voltage versions that can handle up to 1500V DC. It’s crucial to check the specific rating of the connectors you’re using and ensure they match your system’s requirements.

How many MC4 connectors per panel?

Most solar panels come with two MC4 connectors pre-attached – one positive and one negative. These are used to connect the panel to adjacent panels in a string or to the system’s wiring. However, the exact number can vary depending on the panel design and intended configuration.

How do I identify my MC4 connector?

MC4 connectors can be identified by their cylindrical shape with a locking mechanism. The male connector has a protruding pin, while the female connector has a recessed socket. Genuine MC4 connectors often have the manufacturer’s logo or name stamped on them. If you’re unsure, consult with a solar professional or the manufacturer to confirm the connector type.

Final Words

While MC4 connectors remain the industry standard due to their reliability, widespread adoption, and compatibility, T4 connectors offer advantages in terms of higher current capacity. The choice between MC4 and T4 connectors ultimately depends on your specific system requirements, future expansion plans, and local regulations.

For most residential and small commercial installations, MC4 connectors are likely to remain the go-to choice due to their proven track record and wide availability. However, for larger systems or those using high-wattage panels, T4 connectors may offer benefits that outweigh their limited market adoption.