Amorphous vs Monocrystalline Solar Panels | A Detailed Comparison

Solar energy has emerged as a crucial renewable energy source in our quest for a sustainable future. Solar panels, the workhorses of this technology, harness the power of sunlight and convert it into electricity, making them an essential component of solar energy systems.

When it comes to solar panels, two types of silicon dominate the market: amorphous and monocrystalline. These materials, while both derived from silicon, exhibit distinct structural and performance characteristics that influence their suitability for various applications.

Material and Structure

Amorphous Silicon

Amorphous materials lack the highly ordered atomic arrangement found in crystalline solids. Instead, their atoms are randomly distributed, resulting in a non-crystalline structure.

The silicon is typically deposited onto a substrate, such as glass or metal, using techniques like sputtering or chemical vapor deposition (CVD). In these processes, silicon atoms are deposited in a thin-film layer, forming the amorphous structure.

Its layer is relatively thin, usually ranging from a few hundred nanometers to a few micrometers in thickness, allowing for greater flexibility and lighter weight compared to traditional crystalline solar panels.

| Amorphous Silicon Thin-Film Thickness | Value |

| Minimum Thickness | 100 nm |

| Typical Thickness Range | 300 nm – 1 μm |

| Maximum Thickness | 5 μm |

Monocrystalline Silicon

Monocrystalline materials are characterized by a highly ordered atomic structure, with atoms arranged in a repeating pattern throughout the material. This crystalline structure imparts unique properties to the material, such as high electrical conductivity and mechanical strength.

Monocrystalline silicon ingots are grown using the Czochralski process, which involves melting polycrystalline silicon and introducing a small seed crystal. As the seed crystal is slowly pulled from the molten silicon, the atoms align themselves in a single crystalline structure, forming a cylindrical ingot.

Once the ingot has cooled, it is sliced into thin wafers using specialized diamond wire saws. These wafers, typically around 200 micrometers thick, serve as the building blocks for monocrystalline solar cells.

Efficiency and Performance

Conversion Efficiency

Conversion efficiency is a crucial metric for solar panels, indicating the percentage of sunlight that is successfully converted into electrical energy. Here’s how they differ:

| Solar Panel Type | Conversion Efficiency Range |

| Amorphous Silicon | 5% – 7% |

| Monocrystalline Silicon | 15% – 20% |

The higher efficiency of monocrystalline panels can be attributed to their ordered crystalline structure and superior light absorption properties.

Low-Light Performance

The performance of solar panels is not only determined by their conversion efficiency but also by their ability to capture energy from various light conditions.

unlight is composed of a spectrum of wavelengths, each with a specific energy level. Different materials absorb and convert these wavelengths with varying efficiencies.

Amorphous silicon panels excel in low-light conditions, such as cloudy or shaded environments. Their wider light absorption range allows them to capture energy from a broader spectrum of wavelengths, including those in the indirect or diffused sunlight.

Other Considerations

Flexibility

One of the key advantages of amorphous silicon panels is their flexibility, made possible by their thin-film structure. Amorphous silicon panels can be bent or curved, making them suitable for integration into non-flat surfaces like curved rooftops or portable devices.

Monocrystalline panels, on the other hand, are rigid and cannot be bent or flexed without compromising their structural integrity.

Temperature Tolerance

Temperature is another factor that can influence the performance of solar panels. Amorphous silicon panels tend to maintain their efficiency better than monocrystalline panels under high-temperature conditions. This is due to their reduced power loss from heat, making them a more suitable choice for hot climates or installations with limited cooling options.

| Solar Panel Type | Temperature Coefficient (% Efficiency Loss/°C) |

| Amorphous Silicon | 0.1 – 0.2 |

| Monocrystalline Silicon | 0.3 – 0.5 |

Cost

While both types of solar panels have seen significant cost reductions in recent years, there is still a noticeable difference in their pricing. Amorphous silicon panels generally have a lower upfront cost compared to monocrystalline panels.

This cost advantage can be attributed to the simpler manufacturing process involved in producing amorphous silicon panels.

Applications

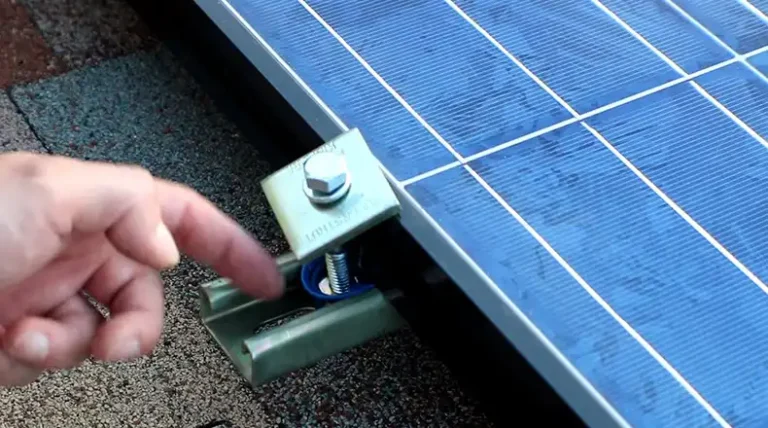

Monocrystalline Applications

Due to their higher efficiency and superior performance, monocrystalline solar panels are often the preferred choice for applications where maximizing power generation is the primary objective.

- Large-scale solar farms, where space is abundant, commonly utilize monocrystalline panels to optimize energy output.

- Residential and commercial rooftop installations also benefit from the higher efficiency of monocrystalline panels, allowing for maximum energy production from limited roof space.

Amorphous Silicon Applications

The unique properties of amorphous silicon panels make them well-suited for certain applications where flexibility, low-light performance, or cost-effectiveness is prioritized.

- Building-integrated photovoltaics (BIPV), where solar panels are integrated into the architectural design of buildings, often employ amorphous silicon panels due to their flexibility and ability to conform to non-flat surfaces.

- Consumer electronics and portable devices, such as solar-powered chargers or outdoor gear, can take advantage of amorphous silicon’s low-light performance and lightweight construction.

- In shaded or partially obstructed areas, where direct sunlight is limited, amorphous silicon panels can outperform their monocrystalline counterparts due to their ability to capture diffused light more effectively.

Additional Considerations

Polycrystalline Silicon

While not as widely used as amorphous or monocrystalline silicon, polycrystalline silicon panels represent a middle ground between the two.

- Polycrystalline panels are made up of multiple crystalline structures, resulting in a balance between efficiency and cost.

- Their efficiency typically falls between amorphous and monocrystalline panels, while their cost is generally lower than monocrystalline but higher than amorphous.

| Solar Panel Type | Conversion Efficiency Range | Relative Cost |

| Amorphous Silicon | 5% – 7% | Lowest |

| Polycrystalline Silicon | 12% – 16% | Medium |

| Monocrystalline Silicon | 15% – 20% | Highest |

Durability and Weather Resistance

The durability and weather resistance of solar panels is an important consideration, especially for outdoor installations subject to harsh environmental conditions.

- Monocrystalline panels are known for their superior durability and resistance to weathering, making them a more reliable choice for long-term installations.

- Amorphous silicon panels, while generally durable, may experience some degradation over time due to their thin-film structure and exposure to environmental factors.

Environmental Impact

As with any technology, it is important to consider the environmental impact of solar panels throughout their lifecycle, from material sourcing and manufacturing to end-of-life disposal and recycling.

- Both amorphous and monocrystalline silicon panels have relatively low environmental impacts during their operational phase, as they generate clean, renewable energy.

- However, the manufacturing processes and material sourcing for each type may have different environmental footprints, which should be taken into consideration when evaluating their overall sustainability.

FAQs

What is the difference in efficiency degradation over time?

Monocrystalline panels tend to have a slower degradation rate, losing approximately 0.5% efficiency per year. On the other hand, Amorphous silicon panels may experience a faster degradation rate, typically around 1% per year.

Can amorphous and monocrystalline panels be combined in a single system?

Yes, it is possible to combine both types of panels in a single solar energy system, although their different characteristics may require separate inverters and charge controllers.

Which type of panel is better for residential vs. commercial installations?

For residential installations with limited roof space, monocrystalline panels are often preferred due to their higher efficiency and space savings. Larger commercial installations may opt for a combination of monocrystalline and amorphous panels, taking advantage of their respective strengths and balancing cost with efficiency.