Types Of Earthing For Solar System Explained

When it comes to solar installations, earthing (also known as grounding) is a critical safety measure that’s often overlooked. But what exactly is earthing, and why is it so important for your solar system?

Simply put, earthing is the practice of connecting electrical equipment to the ground, providing a safe path for excess electricity to dissipate.

In solar installations, proper earthing protects your equipment from damage due to voltage surges, safeguards against electric shocks, and even helps defend against lightning strikes.

There are several types of earthing systems used in solar setups, each serving a specific purpose.

From equipment earthing to array earthing, understanding these different methods is crucial for ensuring the safety and efficiency of your solar power system.

In this post, we’ll break down the various types of earthing for solar systems, helping you grasp why this seemingly simple step is actually a key component of a well-designed and safe solar installation.

Types of Earthing Systems for Solar Installations

Solar installations employ various earthing systems, each serving specific purposes within the overall grounding scheme. Let’s explore the main types:

1. Equipment Earthing

Equipment earthing, also known as protective earthing, focuses on connecting all non-current-carrying metal parts of the solar installation to the ground. This includes:

- Inverter enclosures

- Solar panel frames

- Mounting structures and racks

- Junction boxes and conduits

The primary purpose of equipment earthing is to prevent these metal parts from becoming energized in case of a fault, reducing shock hazards. It’s typically achieved using copper conductors connected to the main earthing system.

2. Lightning and Surge Protection Earthing

Solar arrays, especially those mounted on rooftops or in open fields, are particularly vulnerable to lightning strikes. A dedicated lightning protection system (LPS) is often integrated with the overall earthing system:

- Air terminals (lightning rods) installed at strategic points

- Down conductors to safely route lightning current to ground

- Low-impedance earth termination system

In addition to the LPS, surge protection devices (SPDs) are installed at various points in the system and connected to the earth. These devices divert surge currents to ground, protecting sensitive equipment.

3. Array Earthing

Array earthing refers to the specific grounding requirements for the solar panel array itself:

- DC circuit grounding: Depending on the system design and local codes, one conductor of the DC circuit (usually negative) may need to be grounded.

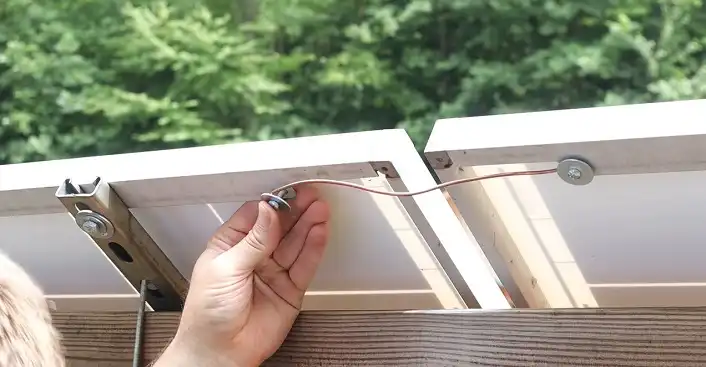

- Frame grounding: All metal frames of the solar panels are interconnected and bonded to the main earthing system.

- Equipotential bonding: Ensures all conductive parts of the array are at the same electrical potential, reducing the risk of stray currents and potential differences.

Proper array earthing is crucial for both safety and performance, helping to mitigate issues like PID and reducing electromagnetic interference.

4. Transformer Earthing

For larger solar installations that include transformers, proper transformer earthing is essential:

- Neutrally earthed systems: The transformer’s neutral point is directly connected to earth, providing a low-impedance path for fault currents.

- Resistance earthed systems: A resistor is placed between the neutral point and earth, limiting fault currents and reducing stress on equipment.

The choice of transformer earthing method depends on factors like system voltage, fault current levels, and protection scheme requirements.

5. Earthing Electrode Systems

The earthing electrode system is the physical connection between the electrical system and the earth. Several types are commonly used in solar installations:

Driven Rods Or Pipes

- Long copper or copper-clad steel rods driven vertically into the ground

- Simple to install and effective in areas with good soil conductivity

- May require multiple rods to achieve desired earth resistance

Buried Electrode Grids

- Network of interconnected conductors buried horizontally

- Provides large surface area contact with soil

- Effective for large-scale installations or areas with poor soil conductivity

Concrete-Encased Electrodes

- Also known as Ufer grounds

- Conductors embedded in concrete foundations

- Particularly effective in dry or rocky soil conditions

- Often used in combination with other electrode types

Ring Earth Electrodes

- Conductor loop buried around the perimeter of the installation

- Helps equalize earth potential and improve lightning protection

- Commonly used in ground-mounted solar farms

The choice of earthing electrode system depends on factors such as soil conditions, available space, system size, and local regulations. Often, a combination of electrode types is used to achieve optimal grounding performance.

Why Earthing is Crucial for Solar Systems?

Proper earthing is a critical component of any solar installation, serving multiple important functions that ensure safety, reliability, and performance. Let’s explore the key reasons why earthing is crucial for solar systems:

Protection Against Electrical Surges

Solar systems are particularly vulnerable to electrical surges, which can come from various sources:

- Lightning strikes: Direct or nearby lightning strikes can introduce massive voltage spikes into the system.

- Grid fluctuations: Sudden changes in grid voltage can propagate through the system.

- Internal system issues: Faults within the solar equipment itself can cause voltage irregularities.

A well-designed earthing system provides a low-resistance path for these excess voltages to dissipate safely into the ground. This protects sensitive electronic components from damage and prevents potential fire hazards.

Without proper earthing, surges could lead to catastrophic failures, resulting in costly repairs or replacements.

Safety for Personnel

One of the primary purposes of earthing is to ensure the safety of anyone working on or around the solar installation:

- Prevention of electric shocks: By maintaining all exposed metal parts at ground potential, the risk of electric shock is significantly reduced.

- Mitigation of touch voltage: Proper earthing minimizes the voltage difference between grounded equipment and a person in contact with it.

- Step voltage protection: In the event of a fault, earthing helps reduce dangerous voltage gradients in the surrounding soil.

For maintenance workers, system owners, and even passersby, a properly earthed solar system provides an essential layer of protection against electrical hazards.

Equipment Protection

Beyond surge protection, earthing plays a crucial role in safeguarding the various components of a solar system:

- Inverter protection: Earthing helps protect inverters from damage due to voltage spikes and electromagnetic interference.

- Panel longevity: Proper grounding of solar panels can prevent potential-induced degradation (PID), extending their lifespan.

- Overall system stability: A good earthing system contributes to the overall electrical stability of the installation, reducing wear and tear on components.

By protecting equipment from electrical stress and interference, earthing helps ensure the long-term reliability and efficiency of the solar system.

Compliance with Regulations

Proper earthing is not just a good practice – it’s often a legal requirement:

- National Electrical Code (NEC): In the United States, the NEC provides specific requirements for grounding and bonding of solar PV systems.

- Local building codes: Many jurisdictions have additional earthing requirements for solar installations.

- Insurance considerations: Proper earthing may be necessary to maintain insurance coverage for the solar system.

Failing to comply with earthing regulations can result in failed inspections, legal liabilities, and potential voiding of equipment warranties.

Common Earthing Methods

When it comes to solar installations, several earthing methods are commonly employed. Each has its own advantages and is suited to different situations. Let’s explore these methods in detail.

Plate Earthing

Plate earthing is a traditional method that uses a large metal plate buried in the ground. Typically made of copper or galvanized iron, this plate acts as the earth electrode.

The plate is usually buried vertically at a depth of at least 3 meters, surrounded by a mixture of charcoal and salt to enhance conductivity.

This method is particularly effective in areas with low soil resistivity and where deep excavation is possible. It provides a large surface area for contact with the earth, which can be beneficial for dissipating high fault currents.

However, plate earthing can be labor-intensive to install and may not be suitable for rocky terrain.

Pipe Earthing

Pipe earthing involves driving a metal pipe into the ground to serve as the earth electrode. The pipe is typically made of galvanized iron or copper and is often perforated to increase its contact with the surrounding soil.

The space around the pipe is filled with a conductive material like charcoal and salt to improve its effectiveness.

This method is relatively easy to install and is suitable for a wide range of soil conditions. It’s particularly effective in areas with moderate soil resistivity.

Pipe earthing is often used in residential and small commercial solar installations due to its simplicity and cost-effectiveness.

Rod Earthing

Rod earthing is similar to pipe earthing but uses solid metal rods instead of pipes. These rods are usually made of copper or copper-clad steel and are driven deep into the ground. Multiple rods can be interconnected to reduce overall earth resistance.

This method is highly versatile and can be used in various soil conditions. It’s particularly effective in areas with high soil resistivity, as the rods can be driven to greater depths to reach more conductive soil layers. Rod earthing is commonly used in both residential and large-scale solar installations.

Mat Earthing

Mat earthing involves creating a network of interconnected conductors buried horizontally in the ground. This “mat” of conductors provides a large surface area for contact with the earth, making it highly effective at dissipating fault currents.

This method is particularly useful for large solar installations or in areas with poor soil conductivity. It helps to equalize the ground potential over a large area, reducing step and touch voltages.

However, mat earthing requires significant excavation and can be more expensive to implement than other methods.

Marconite Earthing

Marconite earthing is a relatively new method that uses a special conductive concrete mixture called Marconite. This material is poured around conventional earth electrodes, significantly reducing the earth resistance.

This method is particularly effective in areas with high soil resistivity or where space is limited. It can achieve low earth resistance values with smaller electrodes, making it ideal for challenging installation environments.

While more expensive than traditional methods, Marconite earthing can provide superior performance and longevity.

Factors to Consider When Choosing an Earthing System

Selecting the right earthing system for your solar installation involves considering several key factors. These considerations will help ensure that your earthing system is effective, compliant, and suitable for your specific installation.

Soil Resistivity

The resistivity of the soil at your installation site is perhaps the most critical factor in choosing an earthing system.

Soil with low resistivity allows for better conduction of electrical current, making it easier to achieve low earth resistance values. In contrast, high-resistivity soil may require more complex earthing solutions.

It’s essential to conduct a soil resistivity test before deciding on an earthing method. This test will help determine the most suitable earthing technique and the depth at which earth electrodes should be installed.

For instance, in areas with high soil resistivity, you might opt for deep-driven rods or Marconite earthing to achieve the required resistance values.

Available Space

The amount of space available for your earthing system can significantly influence your choice of method. Some earthing techniques, like mat earthing, require a large area for installation.

Others, like rod earthing, can be implemented in more confined spaces. Consider not only the current space requirements but also future expansion plans.

If you anticipate expanding your solar installation in the future, you may want to choose an earthing method that can be easily extended or upgraded.

Local Regulations

Compliance with local electrical codes and regulations is crucial when selecting an earthing system. Different regions may have specific requirements for earthing methods, electrode types, and minimum earth resistance values.

Be sure to consult local building codes and utility company requirements. In some cases, you may need to use a combination of earthing methods to meet all regulatory requirements.

System Requirements

The specific requirements of your solar installation will also influence your choice of earthing system. Factors to consider include:

System voltage and current:

Higher voltage and current levels may require more robust earthing systems.

Lightning protection needs:

If your area is prone to lightning strikes, you may need to incorporate specialized lightning protection elements into your earthing system.

Equipment specifications:

Some solar equipment manufacturers may have specific earthing requirements to maintain warranty coverage.

Maintenance and Inspection of Earthing Systems

A well-maintained earthing system is crucial for the ongoing safety and performance of your solar installation. Regular checks and proper maintenance ensure that your earthing system continues to function effectively over time.

Importance of Regular Checks

Earthing systems can degrade over time due to various factors such as soil erosion, corrosion of electrodes, or damage to conductors. Regular inspections help identify and address these issues before they compromise the safety and functionality of your solar system.

Periodic checks also ensure ongoing compliance with regulatory requirements. Many electrical codes mandate regular testing of earthing systems to maintain safety standards.

What to Look for During Inspections

When inspecting your solar installation’s earthing system, pay attention to the following:

Visual Inspection

Check for signs of physical damage or corrosion on visible parts of the earthing system. Look for loose connections, damaged conductors, or signs of tampering.

Earth Resistance Testing

Measure the resistance between the earthing system and the ground. This value should be within the limits specified by local regulations and system requirements. An increase in earth resistance over time may indicate degradation of the earthing system.

Continuity Testing

Verify that all parts of the earthing system are properly connected. This includes checking the continuity between equipment enclosures, solar panel frames, and the main earthing point.

Soil Condition Assessment

Observe the condition of the soil around earth electrodes. Look for signs of erosion, drying, or chemical changes that could affect soil resistivity.

Lightning Protection System Check

If your installation includes a lightning protection system, inspect air terminals, down conductors, and connections to the earthing system.

Documentation Review

Ensure that all earthing system documentation is up to date, including system diagrams, test results, and maintenance records.

Conclusion

Proper earthing is a critical yet often overlooked aspect of solar installations. It plays a vital role in ensuring the safety, reliability, and performance of your solar power system.

From protecting against electrical surges to safeguarding personnel and equipment, a well-designed earthing system is essential for the long-term success of your solar investment.

We’ve explored various earthing methods, each with its own strengths and suitable applications. Whether you opt for traditional plate earthing, versatile rod earthing, or innovative solutions like Marconite earthing, the key is to choose a method that aligns with your specific site conditions, system requirements, and local regulations.