Why Solar Panels Degrade and How to Minimize the Degradation?

Like any other technology, solar panels are subject to degradation over time, which can impact their performance and energy output. Understanding solar panel performance degradation is crucial for accurate financial planning, system maintenance, and ensuring the long-term viability of solar energy investments.

What’s Solar Panel Degradation?

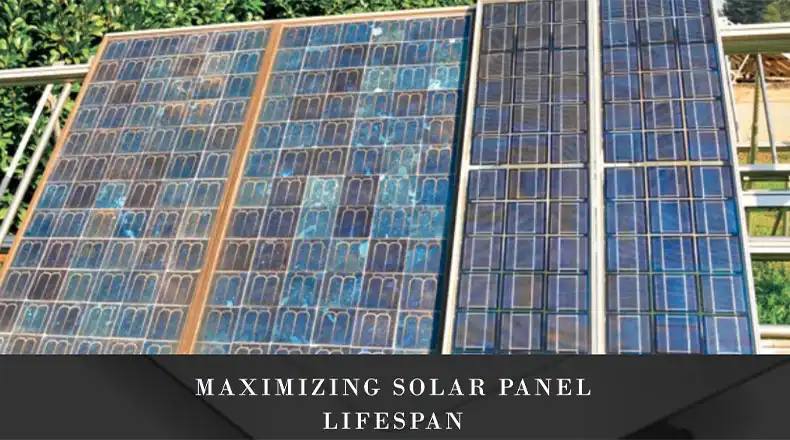

Solar panel performance degradation refers to the gradual decline in a solar panel’s ability to convert sunlight into electricity efficiently. This degradation is an inevitable process that occurs due to various factors, including age, environmental conditions, and material quality.

Typical Degradation Rates (0.5-3% per year)

According to industry standards and research, solar panels typically experience an annual degradation rate ranging from 0.5% to 3%. This means that a solar panel’s power output can decrease by 0.5% to 3% each year compared to its initial rated capacity.

Degradation can follow a linear or non-linear pattern. Linear degradation assumes a constant rate of decline over time, while non-linear degradation may exhibit fluctuations or accelerated rates at certain points in the panel’s lifespan.

Accurately accounting for degradation is crucial when calculating the projected energy output, cost savings, and return on investment for a solar energy system. Underestimating degradation can lead to unrealistic financial projections and potential losses.

Causes of Solar Panel Performance Degradation

Solar panel degradation can be attributed to various age-related factors, environmental conditions, and manufacturing defects. Understanding these causes is essential for implementing appropriate mitigation strategies.

Age-Related Factors

- Light-Induced Degradation (LID):

LID is one of the main factors affecting degradation, particularly in the early stages of a solar panel’s lifespan.

It typically causes an initial rapid drop in efficiency, followed by a stabilization after the first year of operation.

- UV Exposure:

Ultraviolet (UV) radiation from sunlight can damage the back sheet and encapsulant materials, leading to degradation and reduced cell efficiency over time.

- Thermal Cycling:

Solar panels experience extreme temperature fluctuations due to diurnal and seasonal changes, which can cause expansion and contraction stress on the materials.

These thermal cycles can lead to cracking, delamination, and other degradation mechanisms.

Environmental Factors

- Humidity and Moisture:

Damp heat and freeze-thaw cycles can cause moisture ingress, leading to delamination, corrosion, and degradation of internal components.

- Wind, Hail, and Snow Loads:

Extreme weather conditions, such as high winds, hailstorms, and heavy snow accumulation, can physically damage solar panels, resulting in cell cracks, interconnect failures, and performance losses.

- Soiling and Particulate Accumulation:

Dust, pollen, bird droppings, and other particulates can accumulate on the panel surface, reducing light transmission and power output.

- Salt Spray (Coastal Areas):

In coastal regions, salt spray can accelerate the corrosion of metals and coatings, leading to electrical losses and degradation.

Manufacturing Defects

Poor quality materials or workmanship during the manufacturing process can introduce defects that accelerate degradation. Reputable manufacturers with stringent quality control measures and certifications are less likely to produce panels with such defects.

Minimizing Degradation through Panel Selection

Choosing high-quality solar panels with robust materials and advanced technologies can significantly mitigate degradation and extend the system’s lifespan.

Manufacturer Warranties and Degradation Rates

When selecting solar panels, look for panels with a guaranteed linear degradation rate, typically around 0.5% per year or lower. Manufacturers may also provide warranties specifying the minimum power output the panels will maintain over time, such as 90% of the rated power after 10 years and 80% after 25 years.

Newer Panel Technologies (e.g., PERC, Bifacial)

Advanced solar panel technologies, such as Passivated Emitter and Rear Cell (PERC) and bifacial panels, offer improved efficiency and durability compared to conventional panels.

- PERC Technology: PERC cells feature a specialized rear-side passivation layer that enhances light absorption and reduces recombination losses, resulting in higher efficiency and potentially slower degradation rates.

- Bifacial Panels: Bifacial panels can generate electricity from both the front and rear sides, increasing energy yield and potentially reducing the impact of degradation over time.

Quality Assurance and Certifications

When selecting solar panels, look for reputable manufacturers that adhere to industry standards and certifications, such as:

- IEC 61215: This international standard specifies design qualification and type approval requirements for crystalline silicon terrestrial photovoltaic modules.

- IEC 61730: This standard covers construction requirements, testing protocols, and safety qualifications for photovoltaic modules.

- ISO 9001: This certification demonstrates a manufacturer’s commitment to quality management systems and consistent product quality.

Minimizing Degradation with Proper Installation and Maintenance

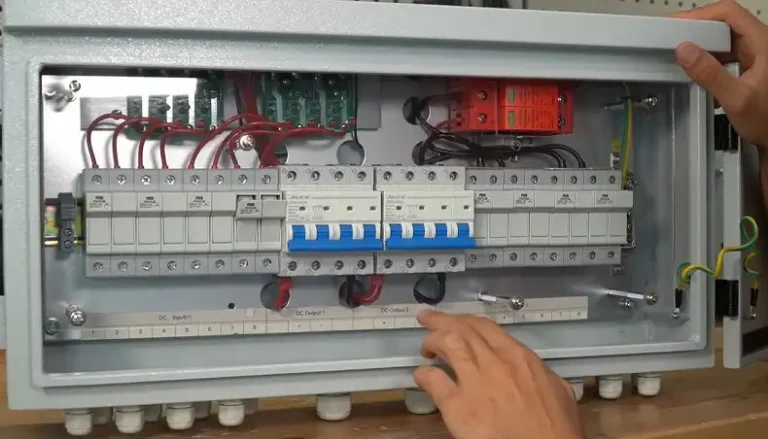

Proper installation and regular maintenance are crucial for minimizing solar panel degradation and ensuring optimal system performance over time.

Site Selection and System Design

- Optimal Tilt and Orientation: Positioning solar panels at the optimal tilt angle and orientation can maximize energy production and reduce the potential for degradation caused by excessive heat or shading.

- Ventilation and Cooling Considerations: Adequate ventilation and cooling measures, such as appropriate racking systems or air gaps, can help dissipate heat buildup and prevent overheating, which accelerates degradation.

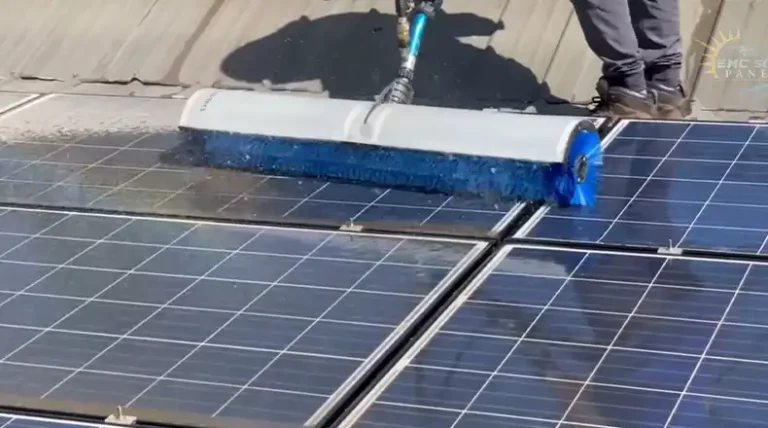

Regular Cleaning and Inspection

- Cleaning Methods and Frequency: Develop a regular cleaning schedule and use appropriate cleaning techniques to remove soiling and ensure maximum light transmission. Avoid abrasive cleaners or methods that could damage the panel surface.

- Visual Inspections for Damage: Regularly inspect solar panels for signs of physical damage, such as cracks, delamination, or discoloration. Early detection and repair can prevent further degradation.

Monitoring and Diagnostic Tools

- Performance Ratio (PR) and Energy Yield Analysis: Monitor the Performance Ratio (PR) and energy yield of your solar system over time. Significant deviations from expected values may indicate degradation or other performance issues.

- Infrared Thermography and Electroluminescence Imaging: Advanced diagnostic techniques like infrared thermography and electroluminescence imaging can detect hotspots, cell cracks, and other defects that contribute to degradation, enabling timely maintenance and repairs.

FAQ

How much do solar panels degrade after 20 years?

After 20 years of operation, good-quality solar panels can be expected to retain around 80-90% of their initial rated power output, assuming an average degradation rate of 0.5-1% per year.

What is the lowest degradation rate for solar panels?

The lowest degradation rates for solar panels are typically around 0.3% to 0.5% per year. Some premium panel manufacturers offer warranties guaranteeing degradation rates as low as 0.3% per year over 25 years.

Can solar panels last 40 years?

While most solar panels are designed and warrantied for 25-30 years, some high-quality panels can potentially last up to 40 years or more with proper maintenance and favorable operating conditions.

End Notes

Solar panel performance degradation is an inevitable process that affects the energy output and financial returns of solar energy systems. Understanding the causes of degradation, such as age-related factors, environmental conditions, and manufacturing defects, is crucial for implementing effective mitigation strategies.

Choosing high-quality panels with robust materials and warranties, following proper installation and maintenance practices, and leveraging advanced monitoring and diagnostic tools can help minimize degradation and extend panel lifespan.